Can pet detection be used in pet food factories?

Leave a message

As a supplier of pet detection solutions, I've often been asked whether pet detection can be effectively used in pet food factories. This is a question that delves into the intersection of animal health, food safety, and the manufacturing processes of pet food. In this blog post, I'll explore the potential applications, benefits, and challenges of implementing pet detection in pet food factories.

Understanding Pet Detection

Pet detection encompasses a range of technologies and methods designed to identify and analyze various aspects related to animals. This can include detecting the presence of specific pathogens, allergens, nutritional components, and even the genetic makeup of the ingredients used in pet food. Some of the key detection techniques we offer as a supplier include Animal Laboratory Testing and Animal Medical PCR Assay. These methods provide accurate and reliable results, which are crucial for ensuring the quality and safety of pet food products.

The Need for Pet Detection in Pet Food Factories

Pet food factories are responsible for producing high - quality products that meet the nutritional needs of pets while also ensuring their safety. There are several reasons why pet detection is essential in these facilities:

1. Pathogen Detection

Pathogens such as Salmonella, E. coli, and Listeria can contaminate pet food during the manufacturing process. These harmful bacteria can cause serious health problems in pets, including gastrointestinal issues, diarrhea, and in severe cases, even death. By using Animal Laboratory Testing, pet food factories can regularly screen their products for the presence of these pathogens. Early detection allows for immediate corrective actions, such as recalling contaminated batches, to prevent the spread of illness among pets.

2. Allergen Identification

Just like humans, pets can have food allergies. Common allergens in pet food include grains, dairy, and certain proteins. Detecting the presence of these allergens in pet food products is crucial for manufacturers to accurately label their products. This helps pet owners make informed decisions about what to feed their pets, especially if their pets have known allergies. Our detection methods can precisely identify the presence and quantity of allergens, enabling pet food factories to produce hypoallergenic or allergen - free products.

3. Nutritional Analysis

Pet food needs to provide a balanced diet for pets. Nutritional analysis through pet detection can determine the levels of proteins, fats, carbohydrates, vitamins, and minerals in the food. This information is essential for formulating pet food that meets the specific nutritional requirements of different types of pets, such as dogs, cats, and small mammals. By ensuring proper nutrition, pet food factories can contribute to the overall health and well - being of pets.

Implementing Pet Detection in Pet Food Factories

Integrating pet detection into the pet food manufacturing process requires careful planning and consideration. Here are some steps that pet food factories can take:

1. Selecting the Right Detection Methods

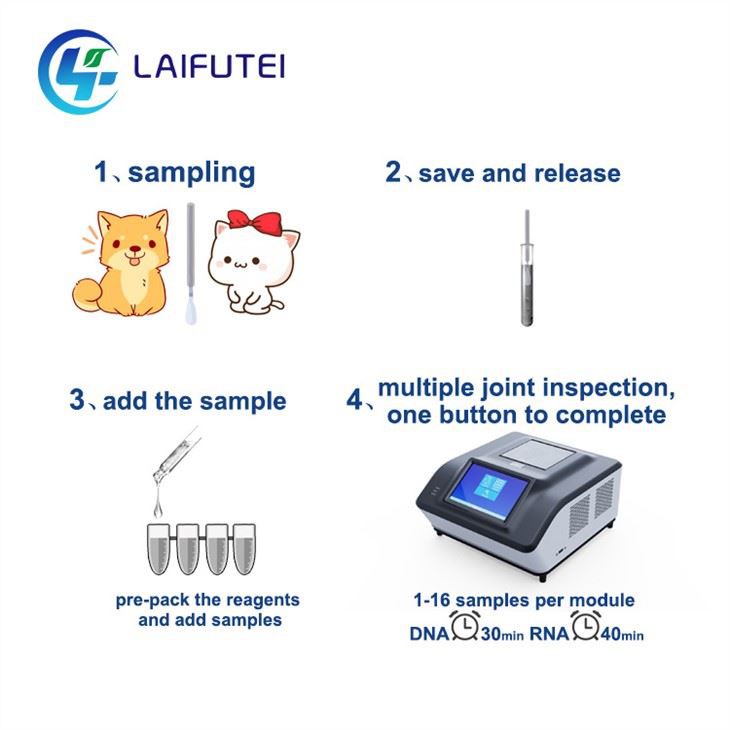

Based on the specific needs of the factory, such as the types of products produced and the potential contaminants or allergens of concern, the appropriate detection methods should be chosen. For example, PCR assays are highly sensitive and can detect even small amounts of pathogens or genetic material, making them suitable for early - stage detection. On the other hand, Animal Laboratory Testing can provide a comprehensive analysis of the nutritional content and the presence of various substances in the pet food.

2. Establishing a Sampling Plan

A well - designed sampling plan is crucial for accurate and representative testing. Pet food factories should determine the frequency of sampling, the locations within the manufacturing process where samples will be taken, and the number of samples to be collected. This ensures that the test results are reliable and can effectively reflect the quality of the entire production batch.

3. Training Staff

Factory staff need to be trained on how to properly collect samples, operate the detection equipment, and interpret the test results. This training ensures that the detection process is carried out correctly and that any issues identified can be addressed promptly.

Benefits of Using Pet Detection in Pet Food Factories

The implementation of pet detection in pet food factories offers several significant benefits:

1. Enhanced Product Quality

By detecting and eliminating potential contaminants and ensuring proper nutritional content, pet food factories can produce higher - quality products. This leads to increased customer satisfaction and loyalty, as pet owners are more likely to trust brands that prioritize the safety and well - being of their pets.

2. Regulatory Compliance

Many countries have strict regulations regarding the safety and quality of pet food. Using pet detection methods helps pet food factories comply with these regulations, avoiding costly fines and legal issues. It also demonstrates the factory's commitment to producing safe and compliant products.

3. Competitive Advantage

In a highly competitive pet food market, factories that can offer products with guaranteed safety and quality have a distinct advantage. Pet detection allows factories to differentiate themselves from their competitors by providing evidence of the high standards of their products.

Challenges of Pet Detection in Pet Food Factories

While the benefits are clear, there are also some challenges associated with implementing pet detection in pet food factories:

1. Cost

The initial investment in detection equipment and the ongoing costs of testing can be significant. This includes the purchase of equipment, the cost of reagents, and the fees for laboratory analysis. However, it's important to view these costs as an investment in the long - term success and reputation of the factory.

2. Technical Complexity

Some detection methods, such as PCR assays, require specialized knowledge and skills to operate. Factories may need to hire trained technicians or provide extensive training to their existing staff. Additionally, the interpretation of test results can be complex, and it may be necessary to consult with experts in the field.

3. Time Constraints

Testing can take time, especially if the samples need to be sent to an external laboratory. This can slow down the production process, especially if there are tight deadlines. Factories need to find a balance between ensuring product safety through testing and maintaining efficient production schedules.

Conclusion

In conclusion, pet detection can play a crucial role in pet food factories. It offers numerous benefits, including enhanced product quality, regulatory compliance, and a competitive advantage. While there are challenges such as cost, technical complexity, and time constraints, these can be overcome with proper planning and investment. As a supplier of pet detection solutions, we are committed to helping pet food factories implement effective detection strategies.

If you're a pet food factory owner or manager interested in learning more about how our pet detection solutions can benefit your business, we invite you to contact us for a detailed discussion. We can provide customized solutions based on your specific needs and requirements. Let's work together to ensure the safety and quality of pet food products.

References

- Smith, J. (2020). Pet Food Safety and Quality Assurance. Journal of Animal Nutrition, 15(2), 123 - 135.

- Brown, A. (2019). The Role of Detection Technologies in the Pet Food Industry. Food Science and Technology Review, 22(3), 201 - 210.

- Green, C. (2021). Nutritional Analysis of Pet Food: Methods and Importance. Animal Nutrition Journal, 18(4), 345 - 356.